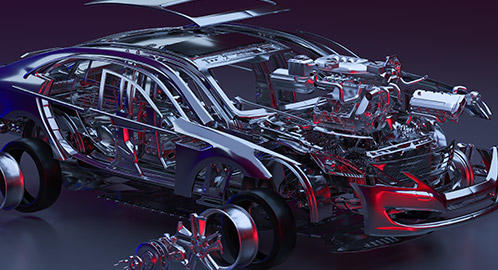

Technique development

|

R & D capabilities

At present, we can not only manufacture products according to customers' samples and drawings, but also can develop independently or realize the simultaneous development with customers according to the boundary dimensions and technical parameters provided by customers, and have successfully practiced synchronous development for many OEMs; The new product development of Shunjiang Company is carried out completely in accordance with the new product development management process specifications (in accordance with IATF16949); In recent years, due to the improvement of research and development capabilities, Shunjiang has successfully developed five categories of products with more than 200 varieties and specifications, and the annual contribution rate of new products is over 20%. |

|

Unified development project team

Refine the development of technical expertise. We will develop the benefits, technical process, and product design from the project, and subdivide tooling and inspection tool design, process documents, etc.; |

|

|

The professionalization of technical process in developing project According to the specialization of the part structure, the company makes full use of the characteristics of mature technical fields, and develops with previous similar experience; |

|

Technical support advantage The company continues to innovate in technology and has an engineering technology center for auto parts, which can achieve independent research and development and has completely independent intellectual property rights. Carrying out scientific and technological cooperation, we cooperate with the School of Materials Science, Engineering of Harbin Institute of Technology and Zhejiang University Hydraulic Forming Engineering Center. Combining the advantages of raw materials and mold technology in China Plastic City and Mold City, we fully integrating regional development and technical strength. |

|

-

Shunjiang Automobile

Ningbo Shunjiang Auto Parts Manufacturing Co., Ltd.

-

- QUICK LINKS

- Home

- About Us

- Product

- News

- Technique development

- Download

- Contact Us

-

- follow us